rockwell hardness c test calculation|rockwell hardness calculation formula : specialty store This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses .

WEBBIG MIKE MC. August 15, 2021. Follow. #Elfuturoseradiferente #BigMikeMC. #504 #Unpasoalavez #PlayingLifeRecords. Comments. #Elfuturoseradiferente #BigMikeMC #504 #Unpasoalavez #PlayingLifeRecords.

{plog:ftitle_list}

A missão Fatal Model é 'organizar e dignificar o mercado de acompanhantes do mundo'. Acompanhantes mulheres, homens e transex de todo o Brasil em mais de 25 mil anúncios ativos. Spotify . Podcast Acompanhadas. Página do Fatal Model no Spotify. Telegram . Bot Telegram para contratantes Canal de novidades Fatal Model Fatal Blog Sua marca no .

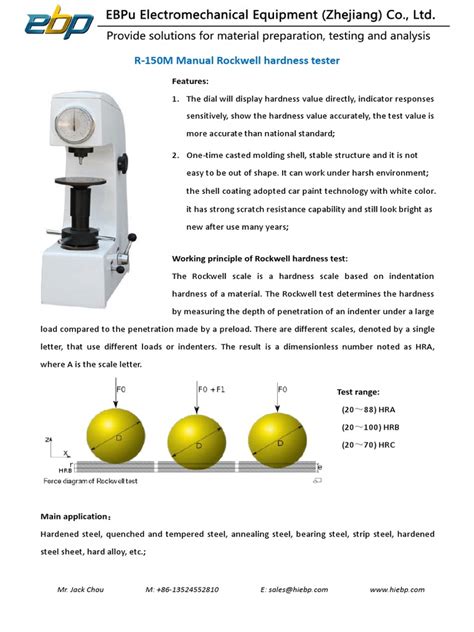

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the . The Rockwell scale is a hardness scale based on indentation .

A Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is barely visible. The .

The Rockwell hardness scale number appears inverse to the depth differential calculation. For instance, a soft Rockwell value is 45, whereas a hard value is 60. What Does a High RC Rating Mean? A high Rockwell C rating .Rockwell C to Brinell Hardness Conversion Chart. While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable .

This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses .Your testing equipment will provide an accurate calculation of the Rockwell hardness result, but there’s a formula to calculate the depth that’s measured into a Rockwell hardness number, which is: HR=N- (d/s) Where the value of: d is .

rockwell hardness testing chart

C = Final position reached by indenter after elastic recovery of sample material. D = Measured distance representing the difference between the pre-load and the position of the large load. This distance is used to calculate the Rockwell .

Then Rockwell testers are used to calculate the values with the help of the Rockwell C hardness standard scale and associate mathematical formula. For example, if you are testing Industrial .This Vickers hardness number calculator uses the size of indentation to return the hardness of the material. There are different scales to measure hardness, including Brinell hardness, Rockwell hardness, Meyers hardness, and .

These approximate relationships between hardness and tensile strength do not apply to nonferrous metals, with the possible exception of certain aluminum alloys. Related: Brinell Hardness Testing Equation. Table A Brinell Hardness to Rockwell Hardness Conversion Table

Rockwell hardness test for plastics: In this test, a load of 15 or 30 kg is applied to the surface of the plastic material for a few seconds. . Using the formula for the Rockwell C scale, we can calculate the Rockwell hardness number .

rockwell hardness tester diagram

Steel Hardness conversion calculator: Brinell Hardness HB: Rockwell C - HRC: Rockwell B - HRB: Vickers - HV : Enter a figure into any of the fields and click calculate, the nearest values in each scale is shown, or zero if out of range. Values are approximate and for guidance only.

The hardness of steel depends on several factors, such as its composition, manufacturing, and heat-treating processes.The different hardness scales use different loads, different indentor shapes, and different measurements to obtain the hardness number. There are no straightforward formulae to establish relationships between the different scales, making .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics. . So no calculation is required to find the hardness value. It is a fast, reliable .

SCOPE. The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials.Brinell [HB] is one of the most common units used for listing the hardness of steel materials. The test is done with a 10 mm steel ball pressed with 3000 Kgf (6,614 Lbf). Common values for machined materials range from 100 HB for very soft materials up to 650 HB for heat-treated steels.. The advantage of Brinell [HB] over Rockwell [HRC/HRB], is that the whole range is .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Conversion table/chart for Brinnel and Rockwell hardness scales and tensile strengths. Buy metals and plastics online in small quantities, cut to order.

See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .For example, the hardness of a steel part could be measured using the Brinell hardness test, but a vendor might specify hardness in Rockwell C scale. In such scenarios, hardness conversion becomes necessary for quality control and to ensure that the material's properties meet the specifications. Key individuals in the disciplineThe Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method . This distance is used to calculate the Rockwell hardness number. A variety of indenters can be used: conical diamond with a round tip for harder metals to ball indenters ranging in diameter from 1/16in to 1/2in for softer materials.Hardness Conversion Formula. Y = aX^2 + bX + c. Where: Y is the hardness value in the target scale; X is the hardness value in the original scale; a, b, and c are constants determined through empirical testing; Example: Converting Brinell (HB) to Rockwell C (HRC) for steels:. HRC = -0.000000567 HB^2 + 0.0624 HB – 13.7. Using this formula, we can convert a Brinell hardness .

rockwell hardness test pdf

To calculate and read the Rockwell hardness value, you need to understand some basic measurement units in this case. In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load . Calculate the Rockwell hardness value: Use the following formula to calculate the Rockwell hardness value:HR = N – (d / D)where HR is the Rockwell hardness value, N is the load applied (in kgf), d is the depth of the .

Hardness is a primary concern when deciding which building materials to use for construction. Performing hardness testing can take many forms, depending on the protocols followed. There are many hardness scales .While the Rockwell hardness testing scale is prevalent, it is best to consider the material thickness and softness to select the most suitable scale between Rockwell B (HRB) and Rockwell C (HRC). This article compares two types of Rockwell hardness to help you find the most ideal of the two for your hardness testing and conversion needs. The concept of the Rockwell Hardness test is essentially similar to its counterparts. A sample material is fed on to either a digital or manual Rockwell hardness tester which would then drop a set load ending with an indenter on the surface. Then, the strength of the material will be determined by the nature of the indentation left on the sample.This formula provides a rough approximation of Rockwell C hardness based on the Brinell hardness value. Keep in mind that different materials may require specific conversion charts. . Example Calculation. For a material with a Brinell hardness of 200: \[ \text{HRC} = \frac{200 - 70}{2} = 65 \] Importance and Usage Scenarios.

This calculator aids in converting Rockwell hardness values to Vickers hardness and vice versa. Historical Background. Hardness testing has a long history, dating back to the early 19th century. Rockwell and Vickers hardness tests are widely used due to their effectiveness in determining a material's resistance to deformation.A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale . The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels. The Rockwell Hardness Conversion Calculator is an invaluable tool for engineers and metallurgists to convert hardness values into different scales, ensuring accuracy in material testing. Deciphering the Rockwell Hardness Conversion Formula Grasp the essence of the Rockwell Hardness Conversion Calculator's formula and its pivotal role in .

abs thickness measurement rules

You can find out more about this alternative method in our guide to Rockwell hardness testing. Hardness testing solutions at Industrial Physics. For all the hardness testing systems you need, whether it’s a hardness pen for testing on the go or a Universal Testing Machine as an addition to your static set up, we’ve got you covered.II. Theory and Principle of the Rockwell Hardness Test. The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. Then a major load is applied to the same spot, which creates a deeper indentation.

How do you calculate Brinell hardness? Brinell hardness is calculated by dividing the load applied (in kilograms-force) by the surface area of the impression made by the indenter (in square millimeters). . HRC (Rockwell C) is a specific hardness scale within the Rockwell hardness testing method.

accurate thickness measurement of graphene

web28 de nov. de 2022 ·